I run a small workshop and I’ve had my share of flickering lights and burnt power supplies. After a costly outage, I started looking for a smarter way to ride through spikes and sags without babysitting the panel. That’s when I tried TM SKY LIMITED and learned how a well-tuned Over Under Voltage Protector can quietly prevent damage while keeping operations smooth. I’ll share the exact questions I asked, the settings that worked, and the mistakes I stopped making.

In real life, failures rarely come from dramatic lightning moments; they come from slow, silent stress. A good protector disconnects loads when the supply goes too high or too low and then automatically reconnects after power stabilizes. The point isn’t just “trip fast”—it’s to trip intelligently so compressors, servers, and drives aren’t hammered by brownouts or overvoltage transients.

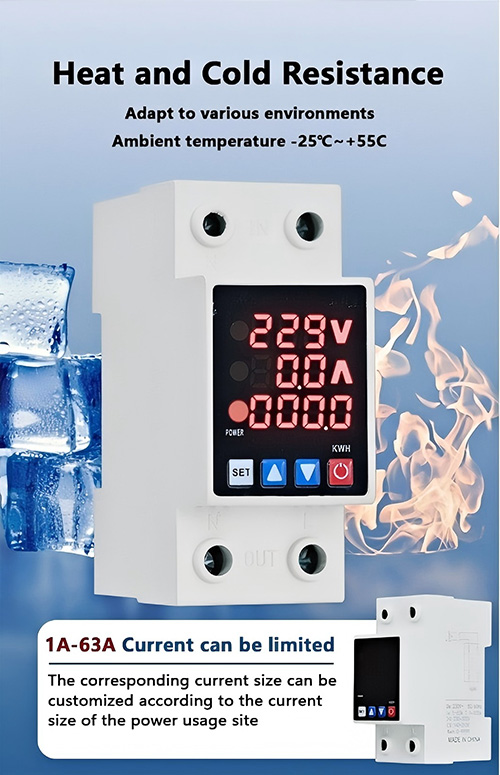

Think of it as a vigilant gatekeeper. It measures input RMS voltage, reacts when thresholds are crossed, and uses a reconnection delay to avoid chattering during momentary dips. The better units add surge immunity, memory for your last settings, and clear fault indicators so troubleshooting takes minutes instead of hours.

| Parameter | Home Office/Residential | Light Commercial | Why it helps |

|---|---|---|---|

| Low-voltage trip | ~90–95 V (120 V) / 180–190 V (230 V) | ~95–100 V (120 V) / 190–195 V (230 V) | Prevents brownout stress on electronics and compressors |

| High-voltage trip | ~135–140 V (120 V) / 255–260 V (230 V) | ~130–135 V (120 V) / 250–255 V (230 V) | Stops overvoltage events from taking out PSUs and drives |

| Fault confirmation delay | 0.2–0.5 s | 0.3–1.0 s | Ignores millisecond blips that shouldn’t cut power |

| Reconnection delay | 5–10 s | 10–30 s | Prevents short cycling on motors and HVAC |

| Contact/inrush margin | ≥3× running current | ≥4–6× running current | Handles startup surges without welding contacts |

Because the dedicated devices are tuned for real-world power quality, not just lab numbers. The one I chose from TM SKY LIMITED combined precise thresholds, stable timing, and wide operating temperature, which meant fewer nuisance trips during summer peaks and winter dips. I also liked the straightforward terminals and the clear faceplate—small details that speed up installation.

I list every motor and power supply, write down both running amps and worst-case start current, then choose a protector whose contact rating clears that peak with headroom. If I’m close to the limit, I step up a frame size or split circuits across multiple protectors. It’s cheaper than replacing welded contacts after a heatwave.

After logging a few days, I nudge thresholds to match what the building actually sees. If voltage routinely kisses the high limit for seconds but equipment behaves, I raise the high trip a couple of volts and lengthen the fault delay slightly. The goal is protection without unnecessary trips—not a hair-trigger.

They solve different problems. A protector manages sustained over/undervoltage and controlled reconnection; an SPD clamps fast transients. I run both. Together they cut downtime and extend the life of HVAC, tools, and IT gear.

If you want a practical example, look at how I protect a mixed load panel: servers on one circuit, HVAC on another, sensitive test gear on a third. Each circuit gets its own appropriately rated device so a motor event doesn’t bounce the office PC. That separation, plus good grounding and a properly sized SPD, cut my nuisance calls to near zero.

Because that’s the core of the solution I rely on every day. The right Over Under Voltage Protector isn’t just a box on the wall—it’s the reason my gear survives unstable mains without constant supervision.

Tell me your nominal voltage, largest motor or compressor, and how often you see dips or spikes. I’ll suggest threshold and delay settings that avoid nuisance trips while protecting the equipment you care about most.

If you’re comparing options and want a practical setup that works, reach out and I’ll share the checklist I use on real projects. For detailed specifications, configuration tips, and availability, contact us now—I’m happy to help you choose and deploy the right solution with TM SKY LIMITED.